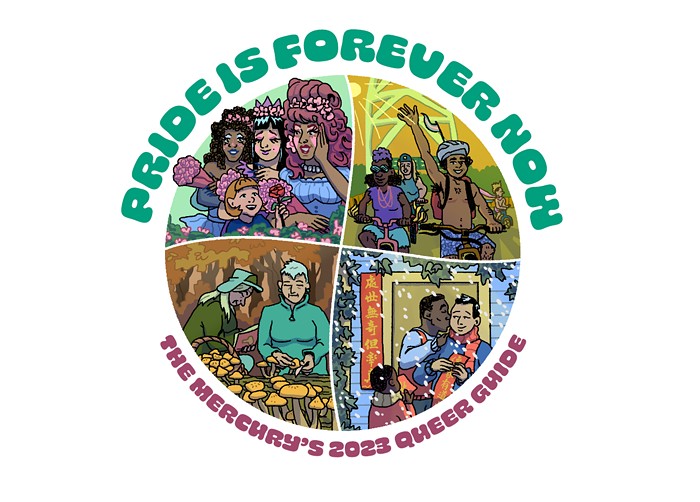

Jeff Mandel never had the intention of becoming a shoemaker, and the trajectory of his life certainly didn't seem to be pointed in that direction. Employed in the tech world as an IT specialist, his career was tooling along just fine until he became obsessed with the trade of handmade shoemaking—a trade that (along with the local butcher, baker, and candlestick maker) has been dying out in the past century. But it is, arguably, primed for revival in a progressive culture that values local production and business along with utopic obsessions with carbon-free this and organic that. It's a movement that, while new to most Americans, is a return to the old ways of Europe, which is exactly where Mandel ended up on his quest to stay true to the methods of the masters.

Beginning with a five-day introduction to shoemaking workshop at the ShoeSchool in Port Townsend, Washington (shoeschool.com), Mandel learned the basics before heading to Europe, where he befriended and informally apprenticed with several masters of the trade. Mandel also took classes alongside students for whom shoemaking was less about exotic fashion design than a traditional way to make an honest living with the skills of your own trained hands.

Back in Portland, Mandel now operates out of a small Southeast studio, where the old industrial machines share space with his computer. (ExIT, the name of his company, means he's an ex-IT guy, but he still does freelance work to pay the bills.) Continually improving on his work through both information sharing with others in the trade and his own innovations, there are continual hurdles to the endeavor. Twice a year there is a footwear materials show at the Oregon Convention Center (the next is September 9 and 10), which basically exists thanks to Nike and Adidas' local headquarters, but when Mandel tried to purchase goods from vendors, they were flabbergasted when he didn't have a factory or shipping address in China—where most of the tanneries are also based. As he put it, "Shoe supplies don't leave China without the shoelaces already on it." (Incidentally, quality laces are hard to get hold of, too.)

Mandel prefers to work with vegetable-tanned leather for several reasons: The alternative, chrome-tanned leather, uses chromium—a toxin—in its processing (even a shoe with a chrome-tanned upper will almost always have vegetable-tanned leather on the inside, where it touches your skin). It also impedes the biodegradability of the leather. Vegetable-tanned leather, on the other hand, is a natural process that predates the Middle Ages and uses the natural enzymes created by bark and leaves floating in still water. Typically, vegetable-tanned leather is stiffer than chrome, which can be made to be very supple and stretchy. The only vegetable-tanned leather that can compete with chrome for softness is found in—you guessed it—Italy. However, as Mandel learned on his trip to the shoe show in Bologna (where unlike the Portland show, vendors were happy to sell him small quantities on the spot), these fine leathers, which carry subtle natural variance in their texture, come at a price. A Chinese leather might be $2.50 per square foot, versus $12.50 for the Italian product. And that was in 2006.

It's little wonder, then, that a pair of ExIT custom shoes rings in at $800 (half is due as an upfront deposit, and the process, which includes a week of you wearing a trial pair to ensure the most ideal fit, can take upward of a month, so you'll have some time to spread out the expense). In return you get a shoe that is not only made specifically for your feet, but also a product that Mandel claims will easily last 10 to 20 years (yes, even if you wear them in the rain). In the meantime, he has also been experimenting with bicycle seats and shoes (pictured here, bottom), with the possibility of fixed sizes (read: less work, lower price) coming down the pipeline. If you can swing it, a pair of ExIT shoes is not only an investment in your own interest, but in the hope that our economy can survive through our willingness and ability to manufacture. Just like in the good old days. (exitshoes.com)